drying bottled media in tyvek after autoclaving|dry cycle after autoclaving : supermarket The number of autoclave cycles that a product can be subjected to depends on the type of glass bottle being autoclaved, with soda lime bottles and plastic-coated bottles able to withstand fewer autoclave cycles than uncoated borosilicate 3.3 laboratory bottles. A waste autoclave is a form of solid waste treatment that uses heat, steam and pressure of an industrial autoclave in the processing of waste. Waste autoclaves process waste either in batches or in continuous-flow processes. In batch processes, saturated steam is pumped into the autoclave at temperatures around 160 °C, or 320 °F. The steam pressure in the vessel is maintained up to 6 bars (gauge) for a period of up to 45 minutes to allow the process to fully 'cook' the waste. The .

{plog:ftitle_list}

With the Belimed ICS 8535 cycle documentation system, which is an available option, we offer an IT-based solution for ensuring seamless traceability of medical devices between reprocessing .Your provider of cleaning and sterilization equipment. Download Belimed Collateral.

If you are sterilizing EMPTY, dry glass labware, autoclave-safe plastic labware, foil-wrapped items, or any other NON-LIQUID item, follow the steps here: 1. Prepare the items for .

elisa test urine

You can invert the bottle if it is tightly capped. Do not shake it or you will introduce bubbles which can result in an uneven agar surface after pouring. With a new paper towel, dry the outside of the bottle before pouring. Now is the time to add acid to PDA, antibiotics, or sterilized sugar solutions. Swirl in two directions to evenly disperse.Tyvek® 1422A autoclave bags with steam indicators can be used as either the inner, or outer bag for the steam sterilization of pharmaceutical change parts.The sterilization pouches are designed for quick, easy presentation of sterile items. .autoclaving and maintains a microbial barrier post . sterilization. The wrapping allows for parts and equipment to be moved throughout the facility and within the clean rooms without compromising the critical product contacting surfaces. Double wrapping or using a wrapping material that is compatible with manual application of surface

drying cycle in autoclave

The number of autoclave cycles that a product can be subjected to depends on the type of glass bottle being autoclaved, with soda lime bottles and plastic-coated bottles able to withstand fewer autoclave cycles than uncoated borosilicate 3.3 laboratory bottles.Autoclave tape with white stripes indicates non-sterile media and tape with dark stripes indicates media that has been sterilized. Autoclave the media. U sage instructions: Check the pressure and temperature gauges to ensure that the autoclave is not running before opening the door. Turn the wheel to open the door slowly, so that any steam .

1. Gilbert AC, Mounier C. Study on the DPTE-BetaBag® Tyvek® Behavior Inside an Autoclave — Part A: Autoclave Cycle Parameters. Study conducted by Getinge La Calhène. July 2019. 2. Gilbert AC, Mounier C. Study on the DPTE-BetaBag® Tyvek® Behavior Inside an Autoclave — Part B: DPTE-BetaBag® Material and Filling Load. The items in my autoclave are not drying and are coming out wet (i.e. wet packs) A wet pack can occur for any number of reasons. There is no single place to look first. There are, however, certain operator behaviors and processes as well as mechanical failures within an autoclave that could lead to the moisture being retained inside an .These covers protect critical surfaces from particulate and microbial contamination, and reduce time-consuming wrapping of components. Pipe Covers are breathable while providing an excellent bacterial barrier for superior performance. Made from Tyvek ®, they are puncture-resistant and extremely tough. Each cover incorporates latex-free elastic . Consult the autoclave manual for assistance in choosing the correct cycle parameters. Autoclave manuals should be stored near the autoclave. Do not attempt to open the autoclave door once the cycle has started. As previously mentioned, autoclave doors feature a mechanical locking mechanism that can be damaged by extreme force.

dry cycle after autoclaving

autoclaving tubes at 121c

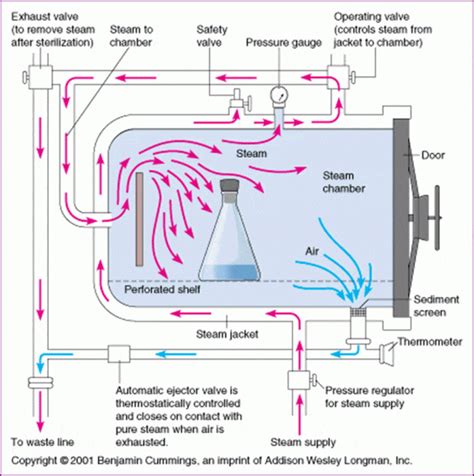

The autoclave consists of a steel container, equipped with a door that can be hermetically sealed from the outside. Through special ducts, the water vapor coming from a boiler is pushed into the autoclave by a pump. The air initially contained in the autoclave is let out until only steam under pressure remains inside it.

Made from 100% Tyvek® and available in almost any size, these steam-sterilizable bags, tubing and wrappers are ideal for very large, heavy or irregularly shaped components such as carboys and stopper tracks or very small parts such as filling needles.

Coated Tyvek is designed to withstand a variety of sterilization methods, including steam autoclaving, ethylene oxide gas sterilization, and gamma radiation. As a lidding material, it ensures that the contents of the package remain sterile after the sterilization process.

These Tyvek® muffs are autoclavable and promote excellent steam penetration and drying during sterilization. These Tyvek® bowl covers can be used amid steam sterilization to reduce time- consuming wrapping of open holders. In addition, each bag can remain in place on the bowl during setup, which minimizes the possibility of contamination .1. Gilbert AC, Mounier C. Study on the DPTE-BetaBag® Tyvek® Behavior Inside an Autoclave — Part A: Autoclave Cycle Parameters. Study conducted by Getinge La Calhène. July 2019. 2. Gilbert AC, Mounier C. Study on the DPTE-BetaBag® Tyvek® Behavior Inside an Autoclave — Part B: DPTE-BetaBag® Material and Filling Load. The sterilizer manufacturer’s drying instructions should be followed; the typical recommendation is to open the door approximately one-half inch (1.25 cm) at the end of the cycle to allow moisture to escape and then initiate the . The number of autoclave cycles that a product can be subjected to depends on the type of autoclavable glass bottle, with soda lime bottles and plastic-coated bottles able to withstand fewer autoclave cycles than uncoated borosilicate 3.3 laboratory bottles.

It is reported that more than 1.4 million people worldwide suffer from hospital-acquired infections, so foregoing autoclaving for any material benefit is not ideal, as autoclaving is one of the .calcium chloride 0.56g, Urea 0.2g, nutrient broth 1.8g; I autoclaved the solution and checked the pH and it was 8.2. I added 1M HCl to it and brought it to my target pH is 7.2.

An effective autoclave or sterilizer must contain dry saturated steam. In order to achieve this, air must be removed from both the load and the chamber which can be . bottled media) will need little air removal and this can be facilitated by automatic air purging. Here the air is allowed to leave the chamber through a vent as steam enters the . The temperature the user has entered exceeds the autoclave’s maximum temperature allowance. Meet the People Behind Our Autoclaves >>> 2. The load is damaged by the autoclave. There are a few ways that an autoclave can damage a load. The first is melting.

3 ANSI/AAMI/ISO 11138: Sterilization of health care products – Biological Indicators 11138-1 –General 11138-2 - EtO 11138-3 - Moist Heat 11138-4 - Dry Heat 11138-5 - Low-temperature Steam and Formaldehyde 11138-7 - Guidance for the selection, use and interpretation of results AAMI/ISO 18472 –Sterilization of health care products – Biological and chemical indicator .If you are using a screw cap media bottle, use a small stir bar to compensate for the indention cavity at the bottom of the bottle. . Low fat dry milk powder. 7 g. DI water. 50 mL. Jensen’s N-Free Medium. Usage: . After autoclaving, allow the medium to cool and add the following antibiotics: Chlortetracycline (0.025 g) Streptomycin (0.025 .uncoated Tyvek® for sterilant permeability. Easy peel-off. Compatible with EO and Gamma sterilization processes. Suitable for bulky items like procedure kits, trays, tubing's, drapes and gowns etc. Easy to transport. Header bags made with Tyvek® enable EO sterilization of medical devices within film-film packages and foil pouches because Tyvek®

The number of autoclave cycles that a product can be subjected to depends on the type of glass bottle being autoclaved, with soda lime bottles and plastic-coated bottles able to withstand fewer autoclave cycles than uncoated borosilicate 3.3 laboratory bottles.

autoclaving at 121c

As we’ve discussed before, the best autoclave procedure for running liquid loads is trickier than just loading up the autoclave and choosing the “liquid cycle.”Follow these four rules and you’ll largely avoid trashing your autoclave chamber, plumbing, and drain while losing your liquids to evaporation, boil over, or burst bottles:Fo Feature for Heat-Sensitive Liquid Media. One last point about liquid sterilization. Laboratory autoclaves are designed to be able to perform the Fo feature (pronounced F-zero).This is a feature that reduces exposure time of the load to high temperatures, in this case delicate heat-sensitive liquid media. Tyvek/plastic – These pouches are for use in Vaporized Hydrogen Peroxide (VHP) and EO sterilization. A sterilization pouch consists of two main parts: medical grade paper, or Tyvek ®, and a clear plastic film, held together by heat seal or with an adhesive. These materials are specifically designed to allow penetration of chemicals, heat .

autoclave drying process

Large autoclaves: Efficient sterilization for big equipment. ASME-compliant, advanced tech, and safety. VERTISA's quality solution.

drying bottled media in tyvek after autoclaving|dry cycle after autoclaving